|

Storm Damage Page 4

This page was last updated on 14 June 2002

Return

to Page 1

Rebuilding

the Anchor Platform Repairs

to the Foredeck Installing

the New Platform

|

|

Repairing

the Damaged Foredeck

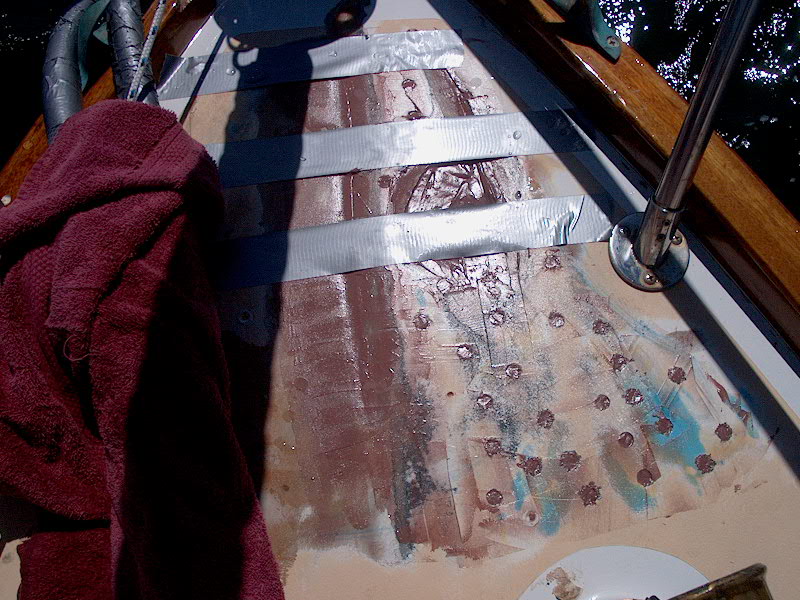

Finally, a good day arrived,

weatherwise, and I prepared to work on the foredeck that was damaged by my

removal of the old anchor platform (as well as some minor delamination).

As early as I could, I was down at the boat in the calm of the morning, and had

it into the dock in short order.

First,

I removed the duct tape over the temporary polysulfide patches I made, and then

scraped off as much of the caulk as I could. Then, armed with my trusty

Porter Cable and some 40 grit discs (ouch!!!), I sanded away the bad material,

some of the deck paint, and beveled the edges as necessary around the broken

areas. The toerail and other parts of the boat were covered with salt

deposits, and of course all the sanding dust stuck perfectly to the salt,

leaving the whole bow of the boat white. Gross! First,

I removed the duct tape over the temporary polysulfide patches I made, and then

scraped off as much of the caulk as I could. Then, armed with my trusty

Porter Cable and some 40 grit discs (ouch!!!), I sanded away the bad material,

some of the deck paint, and beveled the edges as necessary around the broken

areas. The toerail and other parts of the boat were covered with salt

deposits, and of course all the sanding dust stuck perfectly to the salt,

leaving the whole bow of the boat white. Gross!

|

|

Next,

I chucked up a 1/2" bit and drilled a series of holes through the damaged

area and delaminated area that I found during my removal, in preparation for

filling with epoxy and resecuring the deck. The core came up dry in the

holes, which was good news. Next,

I chucked up a 1/2" bit and drilled a series of holes through the damaged

area and delaminated area that I found during my removal, in preparation for

filling with epoxy and resecuring the deck. The core came up dry in the

holes, which was good news.

|

|

I

spent a bit of time sweeping up the copious amounts of sanding dust and

disposing of it; then, because I can't just hose off the area with all the

exposed core, I sponged off the salty, dusty toerails and other areas that I

wouldn't be able to get with a hose, and then washed the whole deck down from

that point aft. (It needed it anyway.) After cleaning the area to be

patched with acetone, I mixed up a batch of epoxy thickened with silica and my

usual low density filler material and applied it into the holes and other areas

as necessary, sealing the whole area, resecuring damaged areas of the deck

laminate, and filling the holes through the delaminated part of the deck to solidify

it. I also filled a small area where I had removed the core that became

exposed as I ground out the top surfaces--or partly filled it, anyway--it will

require another application, or maybe two. To help hold parts of the top

skin down, I duct taped over the top of the repair. I had to be careful an

hour or two later when I returned to my mooring to make sure I didn't drip water

from the lines all over the new epoxy, so I wrapped the lines in a towel until

things dried out a bit, before moving the second line over to the other side

where it belongs. The epoxy cured quickly in the hot sun, so later in the

day I removed the duct tape. I left it to cure fully before continuing. I

spent a bit of time sweeping up the copious amounts of sanding dust and

disposing of it; then, because I can't just hose off the area with all the

exposed core, I sponged off the salty, dusty toerails and other areas that I

wouldn't be able to get with a hose, and then washed the whole deck down from

that point aft. (It needed it anyway.) After cleaning the area to be

patched with acetone, I mixed up a batch of epoxy thickened with silica and my

usual low density filler material and applied it into the holes and other areas

as necessary, sealing the whole area, resecuring damaged areas of the deck

laminate, and filling the holes through the delaminated part of the deck to solidify

it. I also filled a small area where I had removed the core that became

exposed as I ground out the top surfaces--or partly filled it, anyway--it will

require another application, or maybe two. To help hold parts of the top

skin down, I duct taped over the top of the repair. I had to be careful an

hour or two later when I returned to my mooring to make sure I didn't drip water

from the lines all over the new epoxy, so I wrapped the lines in a towel until

things dried out a bit, before moving the second line over to the other side

where it belongs. The epoxy cured quickly in the hot sun, so later in the

day I removed the duct tape. I left it to cure fully before continuing.

|

|

Several

days later, I arrived to fill the remaining hole with epoxy and level the whole

area out. I intend to install a few layers of cloth over most of the area,

so the smoother the better to begin with. My first step was to scrub the

patches with a Scotchbrite pad and water to remove amine blush, then sand the

initial application with 40 grit (by hand, for convenience). Then, I mixed

up more epoxy goop and troweled it in, smoothing everything out as best as

possible. Several

days later, I arrived to fill the remaining hole with epoxy and level the whole

area out. I intend to install a few layers of cloth over most of the area,

so the smoother the better to begin with. My first step was to scrub the

patches with a Scotchbrite pad and water to remove amine blush, then sand the

initial application with 40 grit (by hand, for convenience). Then, I mixed

up more epoxy goop and troweled it in, smoothing everything out as best as

possible.

After a day off, I returned and

once again scrubbed and sanded the new epoxy. I sanded by hand with 40

grit again, just working to get the high spots sanded and the whole area scuffed

up. Final fairing and such will come a little later on.

With that done, I cut several

layers of fiberglass cloth to cover the patch with. Then, I epoxied them

in place, rolling out the layers and making sure they were properly

saturated. The fiberglass covers the entire area of the patch, including

the small holes drilled in the core, the area that I recored (well, filled the

void with epoxy, really...I didn't bother with a new piece of core), and the

seam on the centerline.

|

|

The next day, I washed the new

fiberglass, sanded it (by hand) with 40 grit paper, and troweled on a final coat

of fairing putty--enough to fill the weave of the cloth and help taper out the

edges of the fiberglass layers. The whole patch is

contained within the nonskid area, so I didn't have to compromise the white

Awlgripped strips on the edges of the deck. The next day, I washed the new

fiberglass, sanded it (by hand) with 40 grit paper, and troweled on a final coat

of fairing putty--enough to fill the weave of the cloth and help taper out the

edges of the fiberglass layers. The whole patch is

contained within the nonskid area, so I didn't have to compromise the white

Awlgripped strips on the edges of the deck.

|

|

A

couple days later, I brought the boat back to the dock (for electrical power) on

a beautiful, clear, crisp June day. With my trusty Porter Cable sander and

some 80 grit paper (and subsequently 120 and 220 grit), I sanded the patch

smooth and fair with the surrounding deck areas. I didn't worry about

absolute perfection since most of this area is going to be hidden beneath the

new anchor platform anyway. When I had the whole area sanded to 220 grit

and smooth to my satisfaction, I rinsed off the dust with water (nice being at

the dock) and then, after returning to my mooring, masked off the area I was

going to paint. A

couple days later, I brought the boat back to the dock (for electrical power) on

a beautiful, clear, crisp June day. With my trusty Porter Cable sander and

some 80 grit paper (and subsequently 120 and 220 grit), I sanded the patch

smooth and fair with the surrounding deck areas. I didn't worry about

absolute perfection since most of this area is going to be hidden beneath the

new anchor platform anyway. When I had the whole area sanded to 220 grit

and smooth to my satisfaction, I rinsed off the dust with water (nice being at

the dock) and then, after returning to my mooring, masked off the area I was

going to paint.

|

|

Then,

I primed the raw epoxy areas with Bright side primer; in the warm sun, I was

able to put two coats on in short order. I didn't prime over the painted

deck areas nearby. This picture, taken in brilliant sunlight, might give

you an idea why painting the decks white would not be a good idea! The

glare is brutal. Then,

I primed the raw epoxy areas with Bright side primer; in the warm sun, I was

able to put two coats on in short order. I didn't prime over the painted

deck areas nearby. This picture, taken in brilliant sunlight, might give

you an idea why painting the decks white would not be a good idea! The

glare is brutal.

|

|

When

the primer had had a couple hours to dry, I rolled on a coat of Brightside

Bristol Beige (same as the rest of the deck), using leftover mixed paint from

the initial project (including polymeric particles and flattening agent).

After another hour or so, I rolled on a second coat. I used a small roller

with a 3/16" nap mohair roller cover, and a foam brush to cut in a round

the pulpit bases. It was nice to finally see the ugliness covered after

three weeks in transition since the initial damage occurred. When

the primer had had a couple hours to dry, I rolled on a coat of Brightside

Bristol Beige (same as the rest of the deck), using leftover mixed paint from

the initial project (including polymeric particles and flattening agent).

After another hour or so, I rolled on a second coat. I used a small roller

with a 3/16" nap mohair roller cover, and a foam brush to cut in a round

the pulpit bases. It was nice to finally see the ugliness covered after

three weeks in transition since the initial damage occurred.

All that remains is installing my

new, heavy duty anchor platform. This thing is heavy!!!

|

|

Installing

the New Platform

With

the epoxy securing the stainless steel plate to the wooden platform fully cured,

I removed the clamps and sanded the whole thing smooth with 220 grit. I

cleaned up a little excess epoxy spillout with my sander, but I had been careful

when gluing the pieces together to keep excess epoxy off the varnished wooden

platform, so this was a quick process. With

the epoxy securing the stainless steel plate to the wooden platform fully cured,

I removed the clamps and sanded the whole thing smooth with 220 grit. I

cleaned up a little excess epoxy spillout with my sander, but I had been careful

when gluing the pieces together to keep excess epoxy off the varnished wooden

platform, so this was a quick process.

As time allowed, I applied a

number of coats of gloss varnish (Epifanes) to the wooden sections of the

platform. I ended up with 5 or 6 total coats...a little less than I really

want, but I didn't want to hold up completion and installation any longer.

Varnish is an ongoing task regardless, so I'll just do additional coats once the

platform is reinstalled. When the last (for now) coat of varnish dried, I

bolted the two anchor rollers in place, since I figured it would be easier in

the shop than hanging off the bow of the boat later. After hefting the

platform in the workshop, I decided it would be too heavy to install it with the

rollers bolted in place, so I removed them again.

The next

day, I prepared to install the platform on the boat. Installing it is

not as simple as one might expect, since it requires removing the headstay,

which definitely complicates things a bit. I knew that I could not do the

job alone, so I enlisted the help of Nathan Sanborn (Dasein,

#668), who was more than happy to help out. He couldn't make it till the

afternoon, so in the morning I brought the boat to the dock and loaded the very

heavy (30 lb.) platform on board and prepared a few other things for the installation

later in the day. I removed the jib from the headstay and unrove the

furling line so that we could more easily remove the stay when we needed to, and

got all the tools and such ready.

|

|

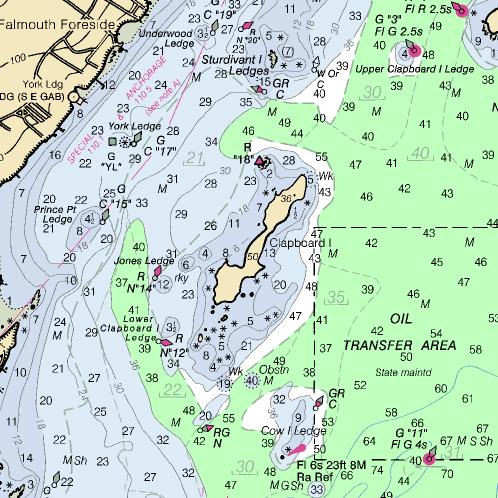

As

the day wore on, a strong southerly breeze began to blow, kicking up quite a

chop in the anchorage--not the best situation for removing stays and working on

the bow. Yuck. I was worried that we would have to postpone the

installation...which I really didn't want to do. In fact, I basically

called it off...but then reconsidered a little later in the afternoon when I

came up with the idea of motoring across the way a mile or so to the lee of

Clapboard Island, where several moorings are installed (in the cove on the left

side of the island on the chart, sort of between the "6" and

"11"; my permanent mooring is near York Ledge, about where the depth

says "28" a little NE of the ledge). With the wind coming from

the direction it was, I thought it might be smooth enough over there to do the

job. Sure enough, the waves were nearly nonexistent, though the wind still

occasionally howled through as the gusts came from more west than south.

But it was OK. Where are the idyllic days of summer, anyway? As

the day wore on, a strong southerly breeze began to blow, kicking up quite a

chop in the anchorage--not the best situation for removing stays and working on

the bow. Yuck. I was worried that we would have to postpone the

installation...which I really didn't want to do. In fact, I basically

called it off...but then reconsidered a little later in the afternoon when I

came up with the idea of motoring across the way a mile or so to the lee of

Clapboard Island, where several moorings are installed (in the cove on the left

side of the island on the chart, sort of between the "6" and

"11"; my permanent mooring is near York Ledge, about where the depth

says "28" a little NE of the ledge). With the wind coming from

the direction it was, I thought it might be smooth enough over there to do the

job. Sure enough, the waves were nearly nonexistent, though the wind still

occasionally howled through as the gusts came from more west than south.

But it was OK. Where are the idyllic days of summer, anyway?

Loosening the backstay as far as

it could go (leaving full threads inside the turnbuckle), we ran the jib halyard

forward to the mooring bit and tensioned it up, pulling the mast forward

somewhat. Then, we unpinned the headstay from the stem and secured it out

of the way temporarily. During the installation, the jib halyard made some

scary sounding creaks and groans as it stretched, so for insurance I ran the

spinnaker halyard up there as well.

|

|

With the headstay out of the way,

I installed the platform to see how it fit and to mark for and drill the

boltholes, as well as mark off the outline of the "feet" so I could

tape around to protect the deck. I had to cut a small bit of the caprail

out so the platform would sit smoothly against the stem, but otherwise the fit

was perfect. (It should have been, since I used the old platform remains

for a template.) Holding it in place, I ran my drill through the predrilled

holes in the platform to mark the deck (after aligning the port side holes with

the existing, but filled, holes in the deck from the old platform) and drew

around the outside of the platform feet with a pencil (obtained from my

handy-dandy pencil rack, of

course). Then, removing the platform again (we had a safety line tied to

it, just in case), I drilled the holes all the way through the deck and taped

off the outline on the deck as well as the platform itself to make caulk cleanup

a little easier.

Using a whole 10 oz. tube of 3M

101 polysulfide caulk, I gooped up the deck beneath the feet, with extra around the

bolt holes, and the flat stem area forward. Then we lowered the platform

into place and pushed a couple of the 3/8" stainless steel bolts through

the holes. At this point, I was getting nervous with the headstay

attached--each wind gust was making the jib halyard creak and groan--so I went

below (with Nathan on deck holding the boltheads) and, squeezing myself into the

chain locker, tightened up the after two bolts on the platform to hold it in

place. Then we reinstalled the headstay, which went fairly smoothly

although we had to crank on the halyard again to pull the mast forward.

|

|

With the headstay safely back in

place, we finished up by securing the remaining four bolts; I only lost one nut

into the chain locker, which was pretty good since I was juggling fender

washers, lock washers and nuts for each of the bolts. (Yes, of course I

had extras...) With all six bolts secured, I cleaned up the excellent

caulk squeezeout with a putty knife and paint thinner. It cleaned up quite

easily--much nicer to clean up 101 than 5200! Suddenly, it looked like my

boat again. The bow just didn't look the same without the bulk of the

varnished platform up there for the couple weeks since the damage occurred.

I was surprised and pleased at how smoothly everything went. Including

motoring time over to Clapboard, we had pretty much wrapped up the worst of the

project within 1-1/2 - 2 hours. With the headstay safely back in

place, we finished up by securing the remaining four bolts; I only lost one nut

into the chain locker, which was pretty good since I was juggling fender

washers, lock washers and nuts for each of the bolts. (Yes, of course I

had extras...) With all six bolts secured, I cleaned up the excellent

caulk squeezeout with a putty knife and paint thinner. It cleaned up quite

easily--much nicer to clean up 101 than 5200! Suddenly, it looked like my

boat again. The bow just didn't look the same without the bulk of the

varnished platform up there for the couple weeks since the damage occurred.

I was surprised and pleased at how smoothly everything went. Including

motoring time over to Clapboard, we had pretty much wrapped up the worst of the

project within 1-1/2 - 2 hours.

We reinstalled the jib on the

furler, cleaned up the tools, and returned across the way to my mooring, where

we enjoyed a well-deserved cold beer. I am thrilled to have this project behind me; now perhaps I can

concentrate on hiding that ugly scar on my hull.

|

|

The

next day, I returned and bolted the two anchor rollers in place. This was

an easy job since the holes were all pre-drilled and ready to go. The

stainless plate on the bottom of the anchor platform acts as a big backing

plate, but I used fender washers and lock washers too. I didn't bring the

anchors back out yet because I didn't feel like bringing the boat into the dock,

but they'll be back on board soon. I reattached the stainless

half-oval molding salvaged from the old platform to protect the platform and the

mooring lines from chafe, and the project was more or less complete. The

next day, I returned and bolted the two anchor rollers in place. This was

an easy job since the holes were all pre-drilled and ready to go. The

stainless plate on the bottom of the anchor platform acts as a big backing

plate, but I used fender washers and lock washers too. I didn't bring the

anchors back out yet because I didn't feel like bringing the boat into the dock,

but they'll be back on board soon. I reattached the stainless

half-oval molding salvaged from the old platform to protect the platform and the

mooring lines from chafe, and the project was more or less complete.

|

|

How will I prevent whatever

happened from happening again? Click here

to see the new anchor storage arrangement.

Click

here to continue with the final repairs to the storm-damaged hull in the bow.

|

|