|

Raw Water Cooling Pump

This page was last

updated on 21 March 2002.

Through a

brilliant feat of design and engineering, the fine folks at Yanmar decided that

it would be entirely inconvenient, difficult, and--basically--unsafe if they

cleverly installed the raw water pump on the engine so that the face place faces

backwards. My hat is off to them. At least the pump is located at

the front of the engine where it can be reached, but sheesh...why did they

decide to install it so that you can't service it without removing the whole

pump? May such marvels never cease.

Anyway, for this

reason (although I would have installed one anyway, regardless of the pump

orientation) I decided to install a Speed

Seal safety cover on the raw water pump. This is a truly clever

design, intended to allow rapid removal of the face plate on the pump for

inspection or emergency purposes. From all I have read, these are well

made and actually work as intended. They feature a custom cover plate,

fitted with an o-ring gasket, that is secured over the top of your existing pump

with knurled thumbscrews--making it easy to remove. Making it even easier

is the fact that only a couple of the screws need be completely removed--the

cover is slotted on one side, so that the opposite screws need only be loosened,

and the plate can slide right off. Ingenious.

I filled out the

order form and faxed it to England, where Speed Seal is located. Almost

immediately, I received a phone call from a very pleasant chap (Alex Parker) who

needed some more information about my particular water pump. Apparently,

the water pump design on the 2GM20F was recently changed, and he wanted to

confirm which pump I had. I didn't have the information he needed right at

hand, so I went out to the boat to remove the pump and check. I would have

had to remove the pump to install the new Speed Seal anyway, so no time like the

present.

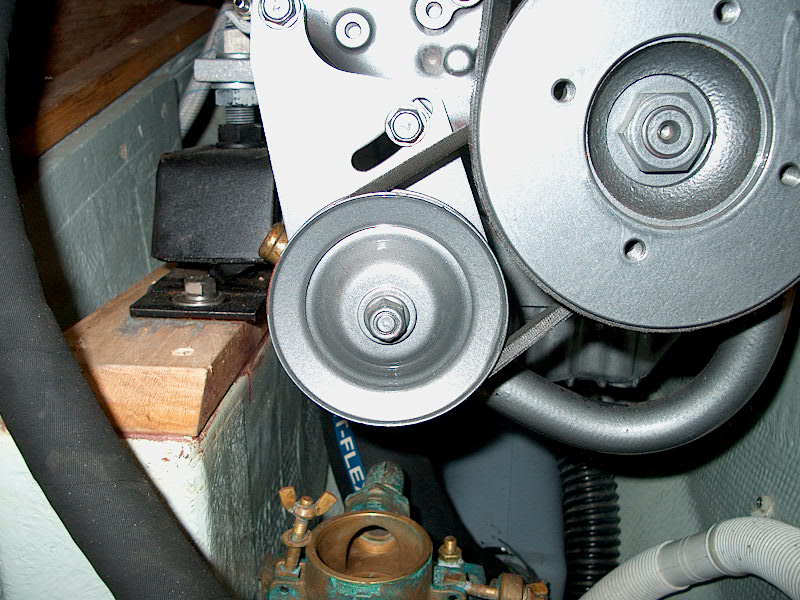

Removing

the pump (that's it behind the small pulley on the left in the photo) was easy,

although it still would be a better design if you didn't have to unbolt it to

check the impeller. There are two bolts that hold the pump in place, one

of which is installed through an adjustment bracket, used to tension the engine

belt that drives the pump. I removed the two bolts and pulled the pump

out. With the pump in hand, I was able to provide Alex with the pump model

number so he could confirm which Speed Seal was the right one. As it

turned out, I have the new style pump (Johnson F4B-903 10 24509-01), which

features its own O-ring on the inside instead of the standard paper

gasket. My service manual, purchased with the engine, does not show

this, so it was an eye opener for me. Apparently, Yanmar didn't see a need

to Removing

the pump (that's it behind the small pulley on the left in the photo) was easy,

although it still would be a better design if you didn't have to unbolt it to

check the impeller. There are two bolts that hold the pump in place, one

of which is installed through an adjustment bracket, used to tension the engine

belt that drives the pump. I removed the two bolts and pulled the pump

out. With the pump in hand, I was able to provide Alex with the pump model

number so he could confirm which Speed Seal was the right one. As it

turned out, I have the new style pump (Johnson F4B-903 10 24509-01), which

features its own O-ring on the inside instead of the standard paper

gasket. My service manual, purchased with the engine, does not show

this, so it was an eye opener for me. Apparently, Yanmar didn't see a need

to  ensure

that the service manual was updated to reflect important changes to the

engine. I wonder what else is wrong. Suffice it to say that I will

be carefully checking all spare parts that I purchase for this engine now,

actually confirming what the part currently on the engine is before ordering the

supposed replacement part. I imagine the standard impeller part number is

incorrect for my pump as well. That would have been a real bummer to find

out in an emergency. Anyway, my new Speed Seal is on its way from England

as we speak. Installation to follow. ensure

that the service manual was updated to reflect important changes to the

engine. I wonder what else is wrong. Suffice it to say that I will

be carefully checking all spare parts that I purchase for this engine now,

actually confirming what the part currently on the engine is before ordering the

supposed replacement part. I imagine the standard impeller part number is

incorrect for my pump as well. That would have been a real bummer to find

out in an emergency. Anyway, my new Speed Seal is on its way from England

as we speak. Installation to follow.

|

|

When

I removed the existing cover plate on the raw water pump for inspection (6 tiny

screws), I found that the impeller, which had been in place all winter, would

not spring back to shape when I removed it--the vanes that had been When

I removed the existing cover plate on the raw water pump for inspection (6 tiny

screws), I found that the impeller, which had been in place all winter, would

not spring back to shape when I removed it--the vanes that had been  compressed

at the top of the pump took a few days to regain their normal shape. The

practical problem behind this is that the pump would not likely have worked

properly if I had used it this way--the vanes would not have sprung back against

the bottom of the pump housing. The lesson here is that your impeller

should probably be removed for long-term storage to prevent this "vane memory".

While I have the pump off, I will be installing a brand new impeller (the

Johnson model number for my impeller is 810). The old one looked OK after

a few days, so I'll keep it as a last-ditch spare (I will also have brand-new

spares on board). compressed

at the top of the pump took a few days to regain their normal shape. The

practical problem behind this is that the pump would not likely have worked

properly if I had used it this way--the vanes would not have sprung back against

the bottom of the pump housing. The lesson here is that your impeller

should probably be removed for long-term storage to prevent this "vane memory".

While I have the pump off, I will be installing a brand new impeller (the

Johnson model number for my impeller is 810). The old one looked OK after

a few days, so I'll keep it as a last-ditch spare (I will also have brand-new

spares on board).

|

|

Exactly a week

after I placed my order, the Speedseal came in the mail. It's a nice

looking piece of gear--simple though it is. It's basically a machined

brass plate that is designed to reproduce exactly the original face plate from a

water pump, combined with knurled screws to fasten it. The picture shows

the inside of the Speedseal--the side that the impeller will bear

against. I ordered extra screws along with it--it only needs four, but I

figured it would be possible to lose one somewhere along the way, so it made

sense to order spares. Exactly a week

after I placed my order, the Speedseal came in the mail. It's a nice

looking piece of gear--simple though it is. It's basically a machined

brass plate that is designed to reproduce exactly the original face plate from a

water pump, combined with knurled screws to fasten it. The picture shows

the inside of the Speedseal--the side that the impeller will bear

against. I ordered extra screws along with it--it only needs four, but I

figured it would be possible to lose one somewhere along the way, so it made

sense to order spares.

Typically, the

Speedseal comes with its own O-ring gasket, which is an additional improvement

for most water pumps as it eliminates the need for an annoying paper

gasket. As mentioned above, however, my Johnson pump on the Yanmar already

had an O-ring gasket, so the Speedseal is just a basic smooth plate designed to

seal against the existing O-ring.

Final

installation calls for some waterproof grease on the threads and gasket.

For demonstration purposes, I reassembled the pump without the grease for the

moment. I'm awaiting a delivery of some new impellers--might as well

replace the one that's in there while the pump is apart (saving the

"old" one as a spare) and will complete assembly and replace the pump

on board once they arrive. I sprung the extra dollar each for the Globe

blue impellers that can run dry for 15 minutes without damage. More

details to follow at that point--along with a discussion on whether or not it

will be feasible now (because of the Speedseal) to change the impeller without

removing the pump from the engine.

|